Article by: Ralph (Dutch740)

Article applies to: all e32 and e34 models. My own car is a 740 made in 1992.

Problem : When you drive off, there is a loud rattling/whining sound from behind the instrument cluster (not to be confused with ABS cycling).

Same noise immediately after switching off the engine. In my case, the tensioner didn’t work at all, which caused the driver’s side wiper to leave a lot of water on the windshield over about 100 km/h.

Possible fix: You can either re-grease the system to stop the noise, or if that doesn’t help, disable it and set the tension manually

Remark from Sean750: “You can also simply disable the wiper tensioner motor by pulling the wiper tensioner relay underneath the rear seat“.

Tools needed: Magnetic tool, torx set, hex set, and some sort of fork-shaped tool (panel puller works fine)

Removing the wiper tensioner:

Start by opening the hood, and removing the cover from the fuse box, as well as the cover over the base of the wiper arm (if it’s still there).

Next, remove the center hex screw (Remark from Sean: it isn’t necessary to remove the center hex screw when you only want to remove the wiper arm without adjusting wiper pressure)

This screw is part of the tensioner system. It’s pushed up by a rod in the center of the shaft (more pictures later). Next, remove the pinch bolt from the wiper arm.

To remove the wiper arm, place a fork-shaped tool like a panel puller under the arm, and move in the direction of the arrow.

If you move it the other way, you will either crack the plastic (bummer) or crack the windshield (time to practice some swearwords):

Next, remove the plastic square plugs (they pull out in one piece if you are careful/lucky). You can now pull up the panel slowly, it’s partially glued down.

You can’t get the whole thing off without removing the passenger side wiper as well, which I thought was too much trouble, so I just propped it up.

It’s quite flexible and you don’t need that much room anyway.

Now, you can see three torx screws that hold the tensioner:

Loosen the three torx screws, the magnetic tool will come in very handy here.

You will notice the rod in the center of the wiper shaft will lower as you lower the tensioner, I suggest securing it with a magnet or such.

If you don’t, it’ll drop out and you will have to get it back in from below and pull it through with a magnet.

Once those three torx screws are loose, the tensioner will drop:

Remove the two connectors from their brackets and unplug them. Remove the wires from the clip on the tensioner.

You can now carefully maneuver out the tensioner. It won’t go out through the top but you can get it out towards the relay box:

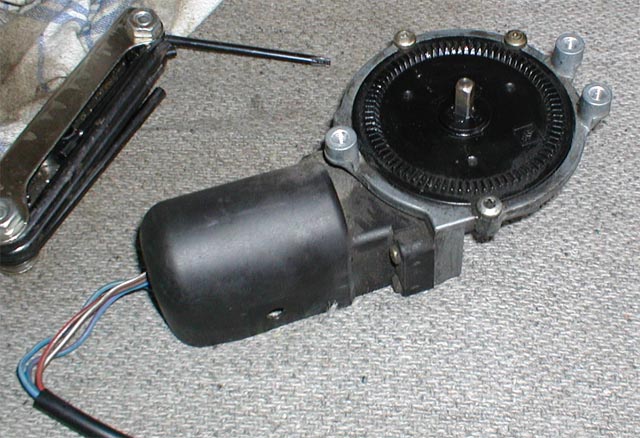

Remove the brass coloured plug from the shaft (just pulls off). You now have the tensioner:

Now, at this point you can do two things. You can set the tensioner manually and disable the motor (by leaving it unplugged, so it’s nothing you can’t undo later. The onboard computer won’t mind either).

Or, you can disassemble the tensioner, and see if you can fix it. If it works but is just noisy, disassembling and re-greasing it may work. See below.

Setting tension manually: Loosen the 3 torx screw on top of the tensioner. Now, rotate the black round plastic ring. As you turn it, the rod in the middle will move up or down.

You want to set it so that it sticks out about 2.5cm, in my case it was about one full turn of the plastic circle. Reinstall the three screws, and then reinstall the brass plug on top of the rod (use some grease so it stays).

Reinstall the tensioner in the car (good octopus-man practice for your hands). If everything is correct, the rod in the center of the wiper shaft should stick out about 1-1.5cm above the shaft.

Reconnect the black plug, but leave the white one unplugged. Secure the wires with tie wraps so there is no chance that they will get caught in the wiper mechanism. Reinstall plastic cover.

Reinstall wiper arm, make sure it’s aligned properly on the splined shaft (the far tip of the wiper blade should be 1-5 cm from the bottom of the windscreen. Reinstall pinch bolt.

Once you tighten the center hex nut, the rod should be pushing up on the hex nut, and as a result, put extra tension on the springs:

Result: No more noise, and much improved wiper performance.

Test drove the car to 170km/h in the rain, and wipers worked just as well as when standing still. I haven’t tried at higher speeds yet, then again I don’t intend to drive 250 in the rain anyway.

Disassembling and re-greasing tensioner:

Clean the cover and area around it. Loosen the 3 torx screws that hold the black round cover, and remove it carefully.

Recover the paper gasket:

You will see three more torx screws, remove these as well. Remove the black cover which is over the motor as well (interference fit).

Lift up the center part, the micro-switch doesn’t need to be removed (the wires just pull through):

You can re-grease the insides of the mechanism.

Basically, there’s a worm drive which turns the middle ring, which in turn drives the square shaft up or down (only works when the black circle cover is on though).

Lift out the white part.

On the side of the housing, remove the 4 philips screws to seperate the motor and gearbox from the worm drive:

This reveals four more philips screws (two already removed on the picture). Remove all four, and open the gearbox.

Be careful, small parts inside that may fall out:

You can test the motor by applying 12V to the connector (on the prongs for the blue wires).

In my case, several teeth had broken off the plastic gear, which made it essentially impossible to fix without getting a new gear.

If the motor works and the gears are undamaged, simply grease everything properly and reassemble it.

A new tensioner is listed in the ETK under part number 67528360246, at over $200.