Article by: Sean

Article applies to: all E32 and E34 models with the LAD “self-leveling” rear suspension.

Problem : this will not be the last article I will write about LAD. Although (at least from my perspective) the system is pretty well designed, you may encounter some problems with it.

One serious problem is leaking of the rear hydraulic struts, caused by a leaking upper seal.

Premature leaking seals can be prevented by a dust cover in good condition. In my case, both dust covers where damaged.

With normal gas shocks, I am not impressed and most of the time I leave it that way. But I do care about my expensive LAD shocks which where replaced about 50 dkm ago. Time to replace the dust covers and it addition, while things are apart, the rubber dampers.

Models : All models equipped with the LAD system (and not the EDC -electronic damper control- system which is a totally different system), although the procedure for the regular gas shock is identical, except the part about disconnecting the high pressure hose.

Remark: all long wheel based 7 series (735iL/740iL/750iL) where equipped with the LAD suspension.

For the short wheel versions it was offered as an (expensive) factory option, but only for Europe and not for the US. Therefore you won’t find a US spec 735i with LAD. Also, this story isn’t applicable for the EDC shocks.

Folks familiar with the European car manufacturer ‘Citroen’ may see some similarities with the suspension system used by this car manufacturer.

The system is almost identical, although the accumulators are mounted separate from the struts, making this a bit different of the original Citroen system.

Also the load leveling system on Mercedes Benz W124 station wagon (1985->) uses this system. Some people report, although is isn’t confirmed yet, that the Mercedes accumulators are identical to the BMW LAD accumulators and that they are much cheaper.

Lets start unbolting parts :

The hard part about the whole procedure is the fact that the rear seat backrest has to be removed, allowing access to the upper strut mounting nuts. This procedure covers the removing of the non-electrical backseats and headrests. This because my car doesn’t have them.

Pull backseat up:

The rear seat back rest is mounted to the chassis with 4 plastic nuts. 2 behind the armrest so remove the Velcro covering the nuts:

Thus revealing the 2 armrest nuts:

And 2 nuts at the backrest corners (one visible here):

Next step is to remove both headrests (also non-electrical type).

Pull them firmly up:

And remove the upper plastic trim of the backrest/seatbelts :

Leave the lower seat belt connector attached and the plastic trim around the seat belt, put plastic trim somewhere in lower backseat area and fully extend the seat belt:

Pull the backrest up and away. You don’t have to remove the backrest entirely:

Pull away the rubber cover, revealing the upper strut mounting.

Don’t unbolt the big center nut, but you can loosen it a turn while its still mounted in the car, making it easier later to remove it.

Don’t unbolt the 3 upper strut mounting nuts yet, but you can also loosen them a few turns:

Sometimes removing the speaker cover panel makes access to the bolts easier:

So much for the interior.

Jack the car up from the rear, place jack stands, remove the rear wheels and depress the brake pedal at least 20 times to discharge the high pressure hydraulic (HP) system.

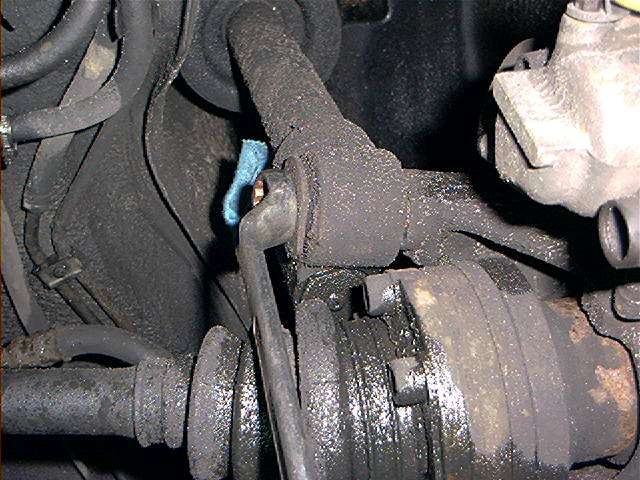

In the wheel wells you should see something like this:

Several warnings in the factory manual and Bentley book can be found about the hydraulic high pressure system.

So once again: absolute cleanliness is necessary when working on the HP system.

When you loosen the nut of the strut, there is a high risk that debris (sand, mud, dirt) falls into the bore of the strut. That is not a good thing.

So I cleaned things up:

And after that I cleaned it with some brake cleaner (or thinner):

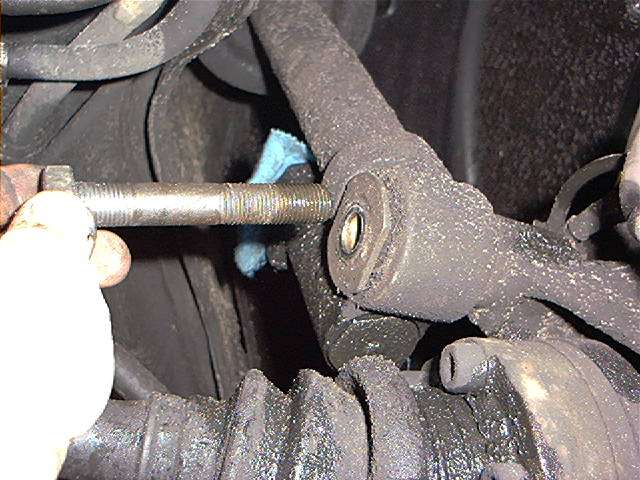

Now unbolt the 14mm nut. I suggest you use a flare open wrench instead of a half-open wrench like I did:

The right side came easily (with some hammering) loose, at the left side I needed a big water pump plier, without damaging the nut to much.

When loosening, a lot of Pentosin will leak out so use a bowl or something like that to catch the fluid:

Remove the HP hose, cover the hole with a small towel to prevent dirt getting in (protect also the loose HP hose with a towel):

Now loosen the big lower bolt (22 mm) of the strut (the oil stains are from the disconnected HP hose):

Now gently hammer the strut loose from the trailing arm, and support the trailing arm with your hand:

When the strut is loose, support the trailing arm with some wood or a jack stand. Don’t let it hang loose:

Now unbolt the 3 upper mounting bolts in the interior.

When loosening the last bolt, support the strut or it will fall right onto the floor or trailing arm:

For some bolts a swivel comes handy:

Gently remove the strut from the rear wheel well, do mind it’s a bit heavy:

When working on the strut, the strut must be in upward position, do not allow it to lie horizontally.

I put it in my vice. To compress the coil, you need some kind of spring compressor.

I made these myself, by an original concept by Gale (see building instructions at Gale’s spring compressor). I made the concept somewhat stronger/beefier and fully welded the bar stock to the conduit:

Before uninstalling the spring, mark the position of the lower spring pad according to the strut. This will make the reinstalling easier (spring removed for better understanding):

Strut clamped in workbench with installed spring compressors:

Be very careful working with spring compressors. Tighten them equally and slowly:

Compress the spring not all the way, just enough so you can turn the spring with your hands. Loosen the big upper mounting nut:

And remove the top upper mount pad:

And remove the top upper mount pad:

Remove spring, rubber damper, pads and dust covers:

The rubber (it isn’t really rubber but some kind of foam) stops/dampers where in bad condition, this is usually the case:

And so were the dust covers:

Because of the very bad condition of the dust covers, a lot of debris can be found on the struts:

This is not a very good thing for my seals, so I cleaned things up a bit with a small brush.

A remark must be made here (with thanks to Gavin Ligget):

This upper seal is simply a wiper seal which serves to keep crud out of the cylinder. It is retained by a taper. This seal does not prevent the release of Pentosin.

If your shock is leaking badly in this area, this is due to internal leakage of the strut.

The strut can be rebuild, check out our section ‘LAD strut rebuild’.

Time to install the new parts (note: the dampers are showed upside down, slight mistake):

Mount the hose onto the rubber stop/damper:

Install the lower pad (mind the previous made markings) and install both parts onto the strut and onto the lower retaining ring:

Now it should look something like this:

Install the spring:

Install coil and upper parts. Pull the shock rod entirely up:

And install upper ring and nut. Make sure the bolt it fully tightened, then remove the spring compressors.

The reinstalling is pretty much the reversal of removal.

With one exception: when reinstalling the strut, tighten the upper 3 mounting nuts just a few turns, do not fully tighten them:

Install the strut onto the trailing arm (lift trailing arm for that) and tighten the big lower bolt:

After this, install the HP hoses and the rear wheels. Remove the jack. At last, tighten the 3 upper bolts.

You don’t bleed the HP system at the shocks. I didn’t bleed the system at all. But you can do it at the LAD regulator valve underneath the car, putting 150 kg (332 lbs) weight in the trunk.

I removed the lid of the LAD fluid reservoir and started the car (wheels on ground).

I saw the reservoir immediately sucked almost empty, while the car was pumping fluid towards the empty rear shocks.

I added almost 1 liter of fresh Pentosin to the reservoir and that about was it. Until now, no problems and no difference in suspension characteristics.

That’s about it. This procedure is pretty straightforward but I say it once again: working with spring compressors can be hazardous or even lethal.

You need to know what you are doing.

Total amount of parts and cost (excl. taxes):

| BMW Part Number | Description | Price | QTY |

| 33531138577 | Rubber damper | $10.44 | 2 |

| 31321125878 | Dust cover | $9.27 | 2 |

You’ll need also about 1 liter of Pentosin fluid to compensate the loss of fluid.

Total amount of time: About 6 hours.

Skills needed/difficulty level: You do have to use spring compressors. If you don’t have any experiences with those tools, the job can be dangerous. You are warned.

Satisfactory level after the job done: Excellent.

Some things I should have done but I overlooked, forgotten, just being too lazy or didn’t replace because I am cheap and now

I am regretting that while everything is reinstalled already and I drove it for a few thousand kilometers/miles?

No, but I just hate to remove that !@# backseat/backrest for this procedure.